HEAVY METHODS OF METHODS

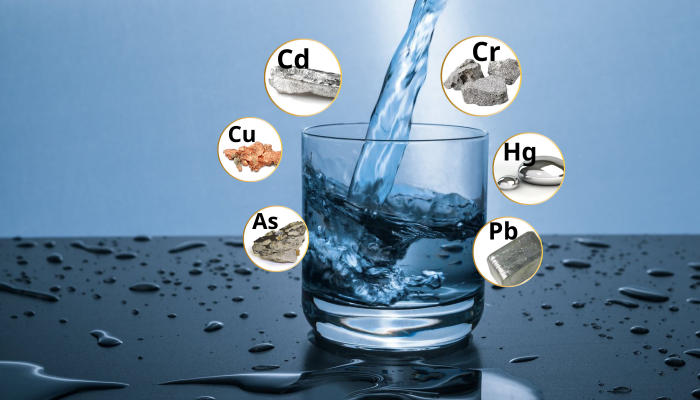

Vietnam is one of the countries facing heavy metal pollution. Pollution sources mainly originate from mining activities, waste treatment and industrial production. These metals such as Cd, Cr, Cu, Ni, As, Pb, Zn… Harmful to human and animal health. It can cause serious health problems such as cancer, impaired nerve and immune system function, impaired reproductive function and brain development in children. Therefore, it is extremely important to treat heavy metals in wastewater before being discharged into the environment.

Sources of heavy metal wastewater Wastewater containing heavy metals is often generated from industrial production activities

Wastewater from the leather industry, textile dyeing, printing ink: contains chromium

Electroplating wastewater: Depending on the metal of the plating layer, the pollution source can be Cu, Zn, Cr, Ni, etc.

Wastewater from paint, battery, and electric cable industries: contains a lot of lead, Pb, and mercury Hg .

Pesticide, rat poison, electronics, glass manufacturing industries: containing Thallium Tl.

Wastewater is treated centrally in the industrial park.

Heavy Metal Treatment Methods

1- Chemical Precipitation Method This is the most common method to remove inorganic wastewater. This method is based on the chemical reaction between the substance introduced into the wastewater with the metals to be separated, at the appropriate pH, a precipitate will form and is separated from the water by the Mn+ + OH- = M deposition method. (OH)n ↓ The commonly used method is the precipitation of metals as hydroxides by simple neutralization of acid wastes. The maximum precipitation pH of all metals does not coincide, we find an optimal pH range, the value is from 7 to 10.5 depending on the minimum value to find to remove metals without causing toxicity. .

Simple, easy to use.

Chemical treatment is cheap and easy to find.

Can handle multiple metals at the same time.

The processing efficiency is also quite high, which is very suitable for large-scale factories.

Defect

With high metal concentration, this method does not handle thoroughly.

Expensive such as transportation, burying when taking the sludge to be treated.

When the precipitate is OH-, it is difficult to adjust the pH for wastewater containing Zn.

2- Method of Adsorption The adsorption method is to use porous materials capable of absorbing dissolved substances on the surface such as activated carbon, peat, iron oxide, synthetic polymer materials… There are two methods of adsorption. Common side effects are physical adsorption and chemical adsorption:

Physical adsorption: is the weak interaction due to electrostatic attraction between heavy metal ions and adsorption centers on the surface of the adsorbent. This method is suitable to recover economically valuable metals, rare metals and regenerate adsorbents.

Chemical adsorption: is a reaction to create chemical bonds between heavy metal ions and functional groups of the adsorbent, or heavy metals will form complexes with the adsorbent. This bond is strong and hard to break, so it is almost impossible to recover the metal as well as not regenerate the adsorbent.

Advantage

- Suitable for wastewater treatment with metal concentration low

- Simple and easy to apply

- The adsorbent is renewable, reducing costs

Defect

- High operating costs due to expensive materials.

- Can only be handled at low concentrations.

3 – Ion exchange method Using synthetic organic resins, hydrocarbon-based macromolecules and functional groups capable of exchanging cations or anions from wastewater. By this method, the physical properties of the substances in solution will not be changed. Positive or negative ions fixed on the columns will repel ions of the same sign to remove them from the water. The advantages of this method are high processing efficiency, simple implementation, small processing space. Able to recover precious metals without creating secondary waste. The disadvantage is that it is not suitable for large-scale production.

Advantage

- Large ion exchange capacity, high metal processing efficiency

- Simple, easy to use

- Small processing space

- Capable of recovering valuable metals, generating no secondary waste.

Defect

- High processing costs are therefore not suitable for large-scale factories

4 – Biological Method This method uses specific microorganisms that can live in water contaminated with heavy metals and accumulate in the biomass. These microorganisms have the following characteristics: have the ability to absorb, store, change the state of heavy metal charge by binding metals in the cell, precipitate, accumulate or encapsulate metal ions. in the mucous membrane outside the cell,… helps convert heavy metal ions into non-toxic form and reduce their content in the environment.. These microorganisms are usually fungi, bacteria or algae… There is also a Some living plant species have the ability to absorb and separate heavy metals such as: Vetiver grass, watercress, fern, guava… The advantage of the method is the high level of heavy metal collection, the surface area. The specific side of biomass is large, low cost. Advantage

- High level heavy metal acquisition

- The specific surface area of biomass is large

- Low cost

Defect

- Large construction area required.

- The generated biomass will contain heavy metals that are difficult to handle.

5 – Electrochemistry (Electrolysis) Method of separating metals from wastewater by using electrodes immersed in wastewater and passing direct current. In the electrochemical process, under the action of electric field, cations will flow to the cathode (cathode) and anions will flow to the positive electrode (anode).

At the cathode, reduction occurs:

- Mn+ + ne → MOTHER

At the anode, anion oxidation occurs:

- Xn- → X + ne Advantages

High metal processing efficiency

No chemicals are used

Defect

- High investment cost, high energy consumption

- Only suitable for wastewater with high metal concentration

See also: Electrolysis technology

MPTEK specializes in applied research and wastewater treatment by electrolysis technology. We provide electrolysis equipment and rent out test runs at a reasonable cost. Contact us now for a consultation and quote. MPTEK SOLUTION COMPANY LIMITED Hotline: 0903188563 Address: 20 Huynh Thien Loc, Hoa Thanh Ward, Tan Phu District, HCMC.