CLEAN AND SUPER CLEAN WATER TREATMENT (RO, UF, DI SYSTEM)

The development of strong industries in Vietnam is also accompanied by an increasing demand for clean water. However, the water environment is gradually polluted, the treatment of clean water for production is a matter of great concern today. Some specific industries need to use ultrapure water for production activities such as pharmaceuticals, cosmetics, electricity – electronics, medical equipment… Water quality requirements are extremely strict.

Solutions for clean and ultra-clean water treatment

Are experts in the field of environment and water treatment. MPTEK specializes in providing clean and ultra-clean water treatment solutions, applying modern and highly effective technologies such as UF (Ultrafiltration), RO (Revers Osmosis), DI (Deionized) (deionized water) technology. …

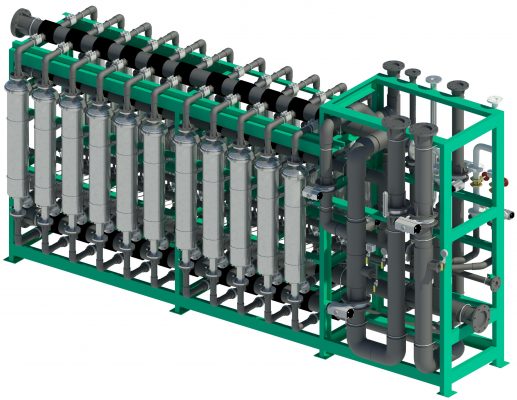

UF (ULTRAFILTRATION) SYSTEM

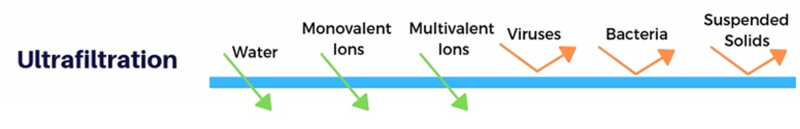

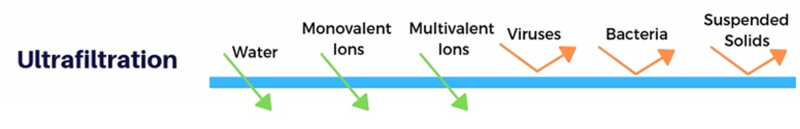

UF stands for Ultra Filtration: Ultrafiltration. UF or ultrafiltration membranes are made from hollow fiber membranes with pore sizes from 0.01 – 0.1 m – micrometers (as small as 1/5000 of the size of a human hair, normally from 50-70 m) capable of filtering. separation of colloids, dissolved solids in water. Removes most suspended solids, bacteria and viruses.

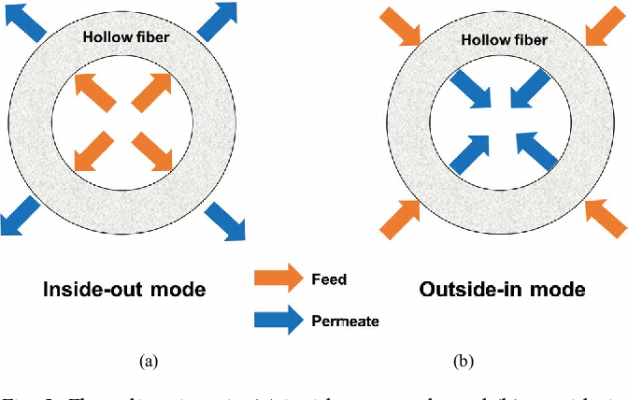

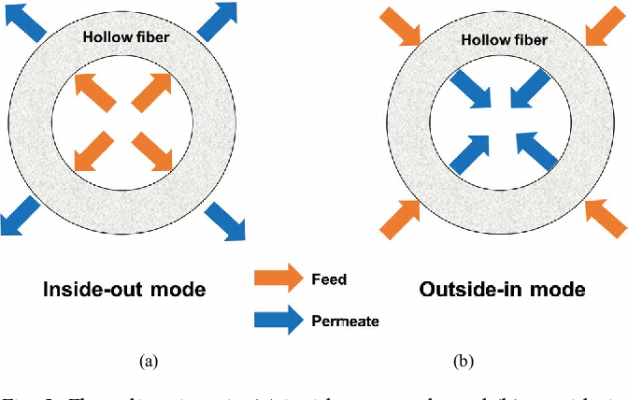

UF stands for Ultra Filtration: Ultrafiltration. UF or ultrafiltration membranes are made from hollow fiber membranes with pore sizes from 0.01 – 0.1 m – micrometers (as small as 1/5000 of the size of a human hair, normally from 50-70 m) capable of filtering. separation of colloids, dissolved solids in water. Removes most suspended solids, bacteria and viruses.  Ultrafiltration membrane can work according to 2 principles: From the outside to the inside: The filter layer is outside the membrane, The water stream with pollutants is pushed in from the outside into the membrane, all harmful substances are stored inside. outside the filter. Only pure mineral water, purified water after filtration is collected inside the filter. From inside out: The filter layer is inside the membrane. The water with contaminants is infiltrated from the inside of the filter. Clean water after filtration is collected outside the filter

Ultrafiltration membrane can work according to 2 principles: From the outside to the inside: The filter layer is outside the membrane, The water stream with pollutants is pushed in from the outside into the membrane, all harmful substances are stored inside. outside the filter. Only pure mineral water, purified water after filtration is collected inside the filter. From inside out: The filter layer is inside the membrane. The water with contaminants is infiltrated from the inside of the filter. Clean water after filtration is collected outside the filter

Application

Domestic water treatment: The water after treatment through the UF filtration system completely meets the standards on quality of drinking water QCVN 01:2009/BYT and domestic water quality QCVN 02:2009/BYT of the Ministry of Health.

Pre-treatment, protection filter for RO system: Helps increase RO membrane life

Concentrate for food and beverage industry, separation and filtration for dairy production, pharmaceutical industry, biology

Filter reusable waste water

Advantage

The filtration process takes place at normal temperature (0~35°C) and low pressure (1~5 bar), so it consumes less power, cutting operating costs significantly. The size of the system is compact, the structure is simple, so it does not take up installation space.

No waste water like RO, big savings for users.

The operation process is simple, does not require a lot of labor.

Membrane structure and materials are homogenous using mechanical filtration, so they do not change the chemical properties of the water source.

The filter material does not penetrate the water source, ensuring purity throughout the treatment process.

Defect

Cannot remove salts dissolved in water

Does not help clean 100% of bacteria and viruses like RO membranes

Easy to clog the membrane when filtering hard and sharp particles larger than 0.1mm. Therefore, a front protection filter is required to ensure the performance of the UF . system at all times

RO FILTERS SYSTEM

RO filter system is a water purification system that uses reverse osmosis membrane technology or RO membrane (Revers Osmosis), which can remove up to 99% of dissolved impurities. Ensure harmful substances such as arsenic, iron, lead, manganese, scale, organic substances present in the water are completely treated.

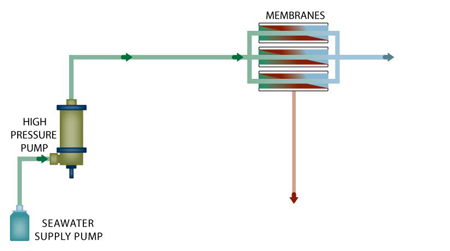

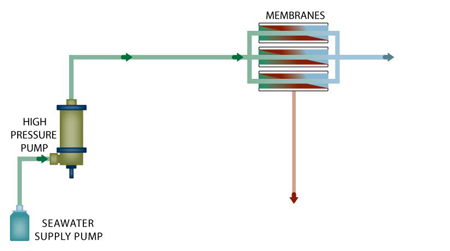

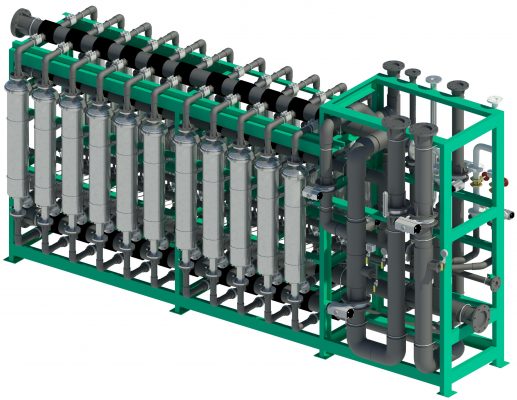

An INDUSTRIAL RO FILTERS SYSTEM IS COMBINED FROM MANY COMPONENTS, INDUSTRIAL RO WATER FILTER EQUIPMENT AND THE MOST IMPORTANTLY IS RO FILTERS RO TREATMENT, FILTERS, AND AFTER RO FILTERS TREATMENT (Depending on WATER QUALITY REQUIREMENTS) PREMIUM TREATMENT SYSTEM IS COMBINEDED FROM MULTIPLE FILTERS, PUMPS, MULTI-FEATURES… GENERAL MISSION TO REMOVE CONTAINS, LARGE LOUD, HEAVY METHODS, ORGANIC SUPPLY, WATER SOFTWARE. WATER IS PUMPED LEVEL 1 FROM CONTAINER INTO THE PRE-TREATMENT AND PRIVACY SYSTEM. AT THIS STEP, WATER IS TREATED THROUGH HEAVY METALLIFEROUS FILTERS, CARBON TREATMENT, SOFTWARE FILTERS, AND REFINITION EQUIPMENT. THE PRINCIPLE STEP IS ONLY PRICE PROCESSING, BUT IT IS VERY IMPORTANT, AVOID DAMAGE OF THE MACHINERY AND HELP THE SUCH OPERATION PROCESS CONVENIENTLY. MAIN SYSTEM – RO FILTER The main system of the RO FILTER SYSTEM can be divided into 2 main parts: HIGH PRESSURE PUMP AND RO FILTER

An INDUSTRIAL RO FILTERS SYSTEM IS COMBINED FROM MANY COMPONENTS, INDUSTRIAL RO WATER FILTER EQUIPMENT AND THE MOST IMPORTANTLY IS RO FILTERS RO TREATMENT, FILTERS, AND AFTER RO FILTERS TREATMENT (Depending on WATER QUALITY REQUIREMENTS) PREMIUM TREATMENT SYSTEM IS COMBINEDED FROM MULTIPLE FILTERS, PUMPS, MULTI-FEATURES… GENERAL MISSION TO REMOVE CONTAINS, LARGE LOUD, HEAVY METHODS, ORGANIC SUPPLY, WATER SOFTWARE. WATER IS PUMPED LEVEL 1 FROM CONTAINER INTO THE PRE-TREATMENT AND PRIVACY SYSTEM. AT THIS STEP, WATER IS TREATED THROUGH HEAVY METALLIFEROUS FILTERS, CARBON TREATMENT, SOFTWARE FILTERS, AND REFINITION EQUIPMENT. THE PRINCIPLE STEP IS ONLY PRICE PROCESSING, BUT IT IS VERY IMPORTANT, AVOID DAMAGE OF THE MACHINERY AND HELP THE SUCH OPERATION PROCESS CONVENIENTLY. MAIN SYSTEM – RO FILTER The main system of the RO FILTER SYSTEM can be divided into 2 main parts: HIGH PRESSURE PUMP AND RO FILTER

High pressure pump and RO . membrane

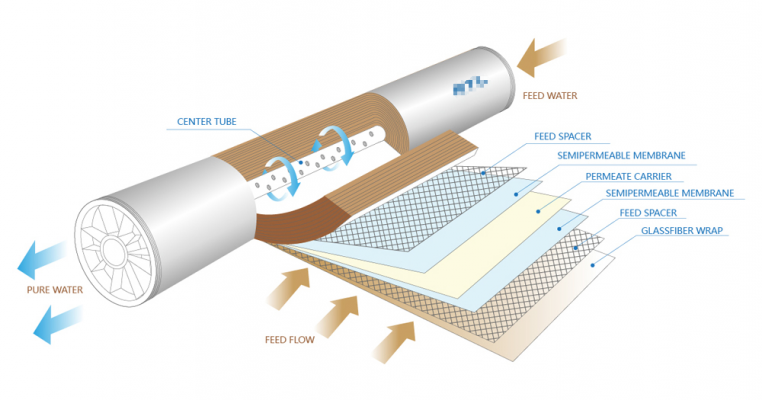

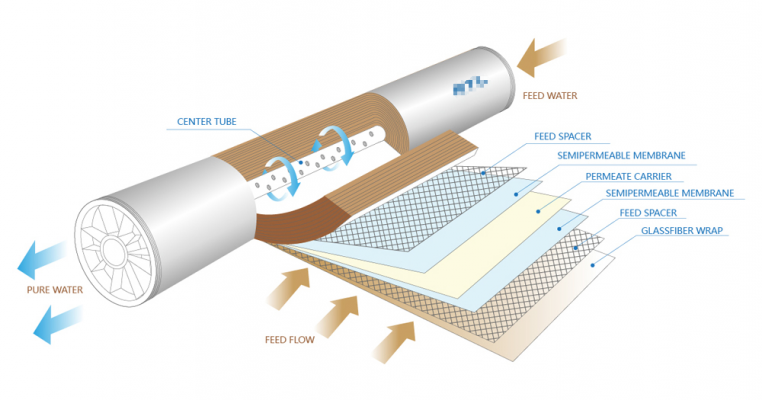

Structure of RO màng membrane

Control part:

- Pretreatment water quality: pH, ORP or Chlorine, Conductivity (TDS), SDI, flow

- Electromechanical and operation: pressure, differential pressure, flow, auto flush

- To increase efficiency and prolong membrane life with chemicals

- Anti-scale chemicals, microbiological control and chlorine.

Periodic CIP

After the RO membrane Depending on the intended use, the next treatment method is selected. Can use UV, Ozone to kill bacteria, or DI treatment system to further reduce ions in water. In residential RO systems, activated carbon filters are often used or mineralized to create a natural sweetness for drinking water.

PROS AND DISEASE SYSTEMS

Advantage

- Create pure water products that meet the standards 6-1-2010/BYT.

- Filtering water according to the principle of reverse osmosis should achieve high filtration efficiency.

- There is a core that adds minerals, creates sweetness and increases the amount of oxygen and pH of the water.

- Capable of self-cleaning when filtering water.

- Removes up to 99% of impurities, toxins and pathogenic bacteria in water.

- Filter pure water from many different water sources: brackish water, tap water, well water, …

- Less filter replacement required.

Defect

- Highly acidic water cannot be used.

- Only 60% pure water is retained. However, the discharged water can be used to clean the house and water the plants.

- Using electricity, if the power is out for a long time, it will cause some inconvenience.

DIDI WATER FILTERING SYSTEM

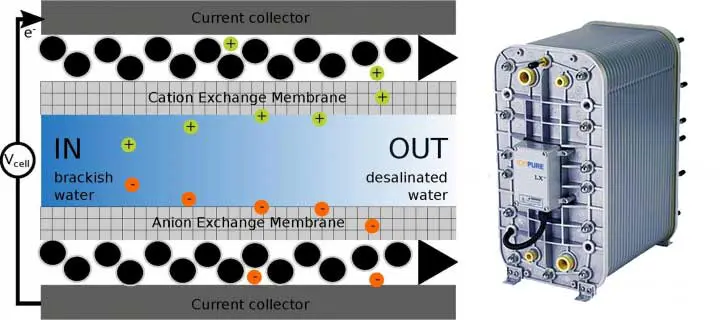

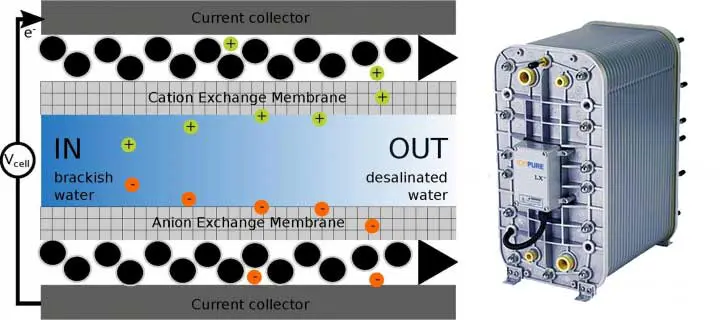

Deionized Water – Deionized Water also known as DI water is the removal of all minerals and ionized salts (both organic and inorganic) from solution through ion exchange. Because most water impurities are dissolved salts, deionization produces a high purity water that can be considered ultrapure water similar to distilled water. Compared with distillation, deionization is faster, less energy intensive and more cost effective. The water after DI treatment reaches a purity level with almost only water molecules remaining (H20) with conductivity index < 3µS/cm. Overview of DI water treatment technology The first technology to produce DI water by distillation. The principle of this technology is to use heat to boil water until it vaporizes, after it evaporates, it will be condensed by a cooling system. The ions in the water will be retained in the non-volatile part, however, the ability to remove ions once is not good, depending on the purpose and requirements of use, it can be distilled 2 times or 3 times. However, this method is often energy intensive and expensive. Normally, DI water is usually produced by ion exchange method by letting water flow through tanks containing positive and negative ions, when the water flows out, there will be no more negative and positive ions. DI water can also be purified by processes including reverse osmosis, carbon filtration, microfiltration, ultrafiltration, ultraviolet oxidation, or electrolysis. In recent decades, a combination of the above processes has come into use to produce high purity DI water. However, sometimes contaminants can still be present and are measured in parts per billion (ppb) or parts per trillion (ppt). Nowadays, modern technology is growing day by day. Many water purification and treatment techniques use electric currents to exchange and dialysis unnecessary ions out of the water source. EDI technology combines ion exchange technology, ion membrane technology and electrodialysis to create the purest water source. EDI differs from ion-exchange resin deionization technology in that there is no need to use chemical substances such as acids and caustic soda.

OPERATION PRINCIPLE OF WATER TREATMENT SYSTEM

DI MIXED BED . WATER TREATMENT SYSTEM

The system works on the principle of ion exchange which removes all types of salts dissolved in water, whereby total dissolved solids (TDS) are removed from water through ion exchange using The cation and anion resin particles control the ions in the water. The plastic beads are like a magnet. When water flows through the tub containing H+ cations, it will attract positive ions (Ca2+, Mg2+, Na+, …) and release H+ ions. 3Resin-H + Ca2+ + Na+ → 2Resin-Ca + Resin-Na + 3H+ Water, after passing through the Cation column, will be led to the column containing Anions, the OH- radical Anions will attract negative ions (HCO3-, Cl-, SO4 2-, …) and release OH- Ion. 3Resin-OH + SO4 2-+ + Cl- → 2Resin-SO4 + Resin-Cl + 3OH- H+ and OH- ions then combine to form water H+ + OH- → H2O Anion and Cation resin particles are saturated. It is necessary to revert the ion supply back to the plastic beads according to the pre-designed cycle. The positive cation resins will be supplied with H+ ions by dilute HCl. Negative Anion particles are supplied with OH- ions with dilute NaOH solution. In fact, in order to bring higher efficiency and bring durability to the equipment, it is necessary to have a degassing unit after the Cation plastic column to remove dissolved gases including CO2, H2S…

EDI . MINERAL SYSTEM

The EDI demineralization system is set up to work according to a certain mechanism. The first is to use an exchange membrane and an electrode to remove dissolved ions from the water. Next, apply advanced electrolysis technology to ionize all water molecules and form OH- and H+ ions. In each EDI module, there are 5 main components: Ion exchange resin, 2 ion exchange membranes and 2 electrodes. In the EDI device there are 2 main compartments:

- Dilution chamber: contains mixed ion exchange resin with pure water or with dilution of ions.

- Concentration chamber: concentrates ions and contains waste water.

EDI water purification technology produces high-quality ultra-pure water. This is the solution for many industries that require ultrapure water, water that completely removes ions. With many outstanding advantages, EDI water purification is a water treatment technology of present and future.

Advantages of DI water filtration system:

- For quick and continuous pure water.

- Using the highest quality, durable Ion exchange resin

- There is a meter showing the conductivity.

- The system is easy to operate and maintain.

- Can be directly connected to any water supply pipe.

Application

DI water is applied in many fields such as: medical, laboratory, research and production of pharmaceuticals, cosmetics, electronic manufacturing, food processing, plating… This deionized water is widely used. widely in our lives, including major industries such as:

- Medical and laboratory applications.

- Application in pharmaceutical water, neutral water

- Applications in the production of microelectronics – semiconductors

- Applications in automobile manufacturing

- Applications in energy research

- Application in food and beverage processing

- Application in industrial water production

- Application in boiler water treatment equipment

To achieve the desired demineralization quality, treatment methods need to be combined to increase treatment efficiency and to suit the specific application and operating conditions for each industry. With different requirements and complexity to increase the purity of finished water, treatment models are often applied such as: RO – RO (RO 2-stage or 3-stage), RO – DI Mixbed, RO – EDI ……Customers need support and advice on clean and super clean water treatment solutions. Please contact us for consultation and quote. With a team of experienced engineers in the field of water treatment, we will bring the best solution for customers. MPTEKI SOLUTIONS CO., LTD Hotline: 0903188563 Address: 20 Huynh Thien Loc, Hoa Thanh Ward, Tan Phu District, HCMC.

UF stands for Ultra Filtration: Ultrafiltration. UF or ultrafiltration membranes are made from hollow fiber membranes with pore sizes from 0.01 – 0.1 m – micrometers (as small as 1/5000 of the size of a human hair, normally from 50-70 m) capable of filtering. separation of colloids, dissolved solids in water. Removes most suspended solids, bacteria and viruses.

UF stands for Ultra Filtration: Ultrafiltration. UF or ultrafiltration membranes are made from hollow fiber membranes with pore sizes from 0.01 – 0.1 m – micrometers (as small as 1/5000 of the size of a human hair, normally from 50-70 m) capable of filtering. separation of colloids, dissolved solids in water. Removes most suspended solids, bacteria and viruses.  Ultrafiltration membrane can work according to 2 principles: From the outside to the inside: The filter layer is outside the membrane, The water stream with pollutants is pushed in from the outside into the membrane, all harmful substances are stored inside. outside the filter. Only pure mineral water, purified water after filtration is collected inside the filter. From inside out: The filter layer is inside the membrane. The water with contaminants is infiltrated from the inside of the filter. Clean water after filtration is collected outside the filter

Ultrafiltration membrane can work according to 2 principles: From the outside to the inside: The filter layer is outside the membrane, The water stream with pollutants is pushed in from the outside into the membrane, all harmful substances are stored inside. outside the filter. Only pure mineral water, purified water after filtration is collected inside the filter. From inside out: The filter layer is inside the membrane. The water with contaminants is infiltrated from the inside of the filter. Clean water after filtration is collected outside the filter

An INDUSTRIAL RO FILTERS SYSTEM IS COMBINED FROM MANY COMPONENTS, INDUSTRIAL RO WATER FILTER EQUIPMENT AND THE MOST IMPORTANTLY IS RO FILTERS RO TREATMENT, FILTERS, AND AFTER RO FILTERS TREATMENT (Depending on WATER QUALITY REQUIREMENTS) PREMIUM TREATMENT SYSTEM IS COMBINEDED FROM MULTIPLE FILTERS, PUMPS, MULTI-FEATURES… GENERAL MISSION TO REMOVE CONTAINS, LARGE LOUD, HEAVY METHODS, ORGANIC SUPPLY, WATER SOFTWARE. WATER IS PUMPED LEVEL 1 FROM CONTAINER INTO THE PRE-TREATMENT AND PRIVACY SYSTEM. AT THIS STEP, WATER IS TREATED THROUGH HEAVY METALLIFEROUS FILTERS, CARBON TREATMENT, SOFTWARE FILTERS, AND REFINITION EQUIPMENT. THE PRINCIPLE STEP IS ONLY PRICE PROCESSING, BUT IT IS VERY IMPORTANT, AVOID DAMAGE OF THE MACHINERY AND HELP THE SUCH OPERATION PROCESS CONVENIENTLY. MAIN SYSTEM – RO FILTER The main system of the RO FILTER SYSTEM can be divided into 2 main parts: HIGH PRESSURE PUMP AND RO FILTER

An INDUSTRIAL RO FILTERS SYSTEM IS COMBINED FROM MANY COMPONENTS, INDUSTRIAL RO WATER FILTER EQUIPMENT AND THE MOST IMPORTANTLY IS RO FILTERS RO TREATMENT, FILTERS, AND AFTER RO FILTERS TREATMENT (Depending on WATER QUALITY REQUIREMENTS) PREMIUM TREATMENT SYSTEM IS COMBINEDED FROM MULTIPLE FILTERS, PUMPS, MULTI-FEATURES… GENERAL MISSION TO REMOVE CONTAINS, LARGE LOUD, HEAVY METHODS, ORGANIC SUPPLY, WATER SOFTWARE. WATER IS PUMPED LEVEL 1 FROM CONTAINER INTO THE PRE-TREATMENT AND PRIVACY SYSTEM. AT THIS STEP, WATER IS TREATED THROUGH HEAVY METALLIFEROUS FILTERS, CARBON TREATMENT, SOFTWARE FILTERS, AND REFINITION EQUIPMENT. THE PRINCIPLE STEP IS ONLY PRICE PROCESSING, BUT IT IS VERY IMPORTANT, AVOID DAMAGE OF THE MACHINERY AND HELP THE SUCH OPERATION PROCESS CONVENIENTLY. MAIN SYSTEM – RO FILTER The main system of the RO FILTER SYSTEM can be divided into 2 main parts: HIGH PRESSURE PUMP AND RO FILTER