WASTE WATER TREATMENT BY Liquefied FENTON TECHNOLOGY (FBR-FENTON)

INTRODUCE

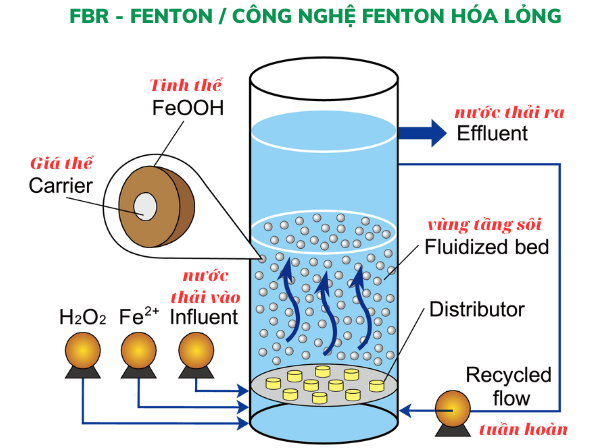

Fluidized Bed Reactor Fenton technology (FBR-Fenton for short) is a technology based on the principle of improvement from traditional Fenton technology to increase processing efficiency and reduce operating costs. This method is classified as an advanced oxidation process (AOPs, Advanced Oxidation Processes) which reacts with the generation of free hydroxyl radicals OH*, the hydroxyl radical *OH is the strongest oxidizing agent after fluorine. Basically, Fenton technology uses iron ions Fe2+ as a hydrogen peroxide (H2O2) catalyst to oxidize organic substances in wastewater. This reaction produces free OH* radicals which are highly oxidizing and can mineralize the pollutant to CO2 and H2O The Fenton reaction produces hydroxyl radicals shown in the following equation: H2O2 + Fe2+ → ‧ OH + OH- + Fe3+ → Fe(OH)3 ↓ The liquefied Fenton method (Fenton IV, FBR-Fenton) is a new technology that combines the functions of a homogeneous Fenton process (Fenton reaction:H2O2+ Fe2+) , heterogeneous Fenton process (H2O2/FeOOH)), fluidized bed crystallization and reductive dissolution of FeOOH. The use range is COD <500mg/L, which can reduce the iron(II) use by almost 50% and reduce the sludge produced by the traditional Fenton method by more than 60%, making the operating cost of the treatment plant significantly reduced.

ADVANTAGES OF FENTON TECHNOLOGY TO Liquefaction

- Environmentally friendly:Unlike other chemicals such as bleach (sodium hypochlorite), it is easy to produce toxic substances such as organochlorine etc that are harmful to the environment.

- Occupies a small space:The oxidation rate of organic matter is quite fast, the retention time is short, about 0.5 to 2 hours is enough, and the normal biological treatment takes about 12 to 24 hours. Due to the short retention time, the capacity of the reaction tank is relatively small, which can save space.

- High flexibility:During operation, when the COD concentration changes, just increase or decrease the amount of Fe2+ and H2O2 chemicals used

- Easy to operate:Just need to supply chemicals and adjust pH, not difficult for most operators.

- Low initial cost:Compared with general biological treatment system, only about 1/3~1/4 of investment cost is required.

- High oxidizing capacity:the hydroxyl radical (‧OH) produced has a strong oxidizing power and can handle a variety of toxic substances such as vinyl chloride, BTEX, chlorobenzene, 1,4-Dioxane, aldehydes, pentachlorophenol, polychlorinated biphenyls, TCE, DCE, PCE and is also effective in treating other EDTAs and ketones such as MTBE, MEK.

APPLICATION

For the treatment of wastewater of the chemical, artificial fiber, textile, paper, dyeing industries, etc., after biological treatment, the color removal and COD treatment are on discharge standard A (QCVN40:2011BTNMT). ) is very difficult, the use of liquefied Fenton technology (FBR-Fenton) after microbiological treatment to achieve the discharge standard of column A (QCVN40:2011BTNMT) is the most economical and effective solution today.